"Holistic" Approach to Cellulosic Ethanol and More

Researchers in Denmark are learning to make the most of cellulosic materials to make bio-fuels. This can only make the economics of biofuels that much more favorable.

A pilot project seeking to maximize the amount of biofuels produced from lignocellulosic materials has officially opened a pilot plant at the Danish Technical University (DTU) in Lyngby, Denmark.Read more at the source.

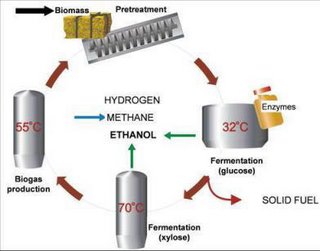

The processes underlying the MaxiFuels project were developed at DTU and spun-off into a new company earlier this year: Biogasol. The main product is cellulosic bioethanol, but the process is also focused on the production of methane (from a biogas process) and hydrogen (from xylose fermentation) as well as other valuable by-products from the parts of biomass not suitable for ethanol production.

The full consumption of available carbohydrates in the feedstock for the production of such a range of product is intended to make the process much more cost-effective. The process also recirculates and reuses all streams produced in the integrated process—process water is reused with the integration of the biogas cycle, for example, further reducing cost and environmental impact of production.

The Biogasol process has four main stages:

1. Pre-treatment. Biogasol uses a combination of combination of steam-explosion and wet oxidation it calls “West Explosion”. Wet Explosion applies both the addition of oxygen and a pressure release at high temperature (170° C to 200° C). Biogasol calculates that this method—for which it has filed a patent—will deliver more sugar at lower cost than other processes. The method works for opening up all major biomass materials: straw, corn stover, bagasse and woody materials.

2. Hydrolysis and glucose fermentation. The Biogasol process combines hydrolysis and fermentation. The BioGasol Concept produces its enzymes for hydrolysis at the plant using an enzyme-producing fungus strain developed in collaboration with Novozymes A/S.

The main products from the enzymatic hydrolysis are the sugars glucose and xylose. The glucose is simultaneously fermented into ethanol by yeast. After fermentation the process stream is separated into a solid and a liquid fraction. The liquid fraction then moves to the xylose fermentation reactor.

3. Xylose fermentation. Xylose is the second-most abundant carbohydrate monomer after glucose, and constitutes between 10-40% of the total carbohydrates in lignocellulosic biomass. Fermentation of both xylose and glucose is therefore a crucial step forward in reducing the cost of ethanol production from lignocellulosic raw materials.

In the Biogasol process, a thermophilic anaerobic bacterium converts both hexose and pentose into ethanol or ethanol/hydrogen in an immobilized reactor at 70° C. Bioethanol is distilled out as a part of the re-circulation loop of the reactor and a fraction of the ethanol can be collected directly from the out-gas stream leaving the reactor due to the high process temperature. This step is unique and one of BioGasol’s patented processes. Wastewater from the xylose fermentation is afterwards transferred to the anaerobic digester.

4. Biogas production and recirculation of the process water. The remaining non-carbohydrate organics move to an anaerobic digester along with the wastewater stream for the production of biomethane.

Biogasol calculates that from 1,000 kg of rice straw, its process can produce 310 liters of ethanol; 90 cubic meters of biogas, and 230 kg of solid biofuel.

Also, take a look at this attempt to use microbes to produce hydrogen from cellulose at Brookhaven Labs.

Labels: biofuels

0 Comments:

Post a Comment

“During times of universal deceit, telling the truth becomes a revolutionary act” _George Orwell

<< Home